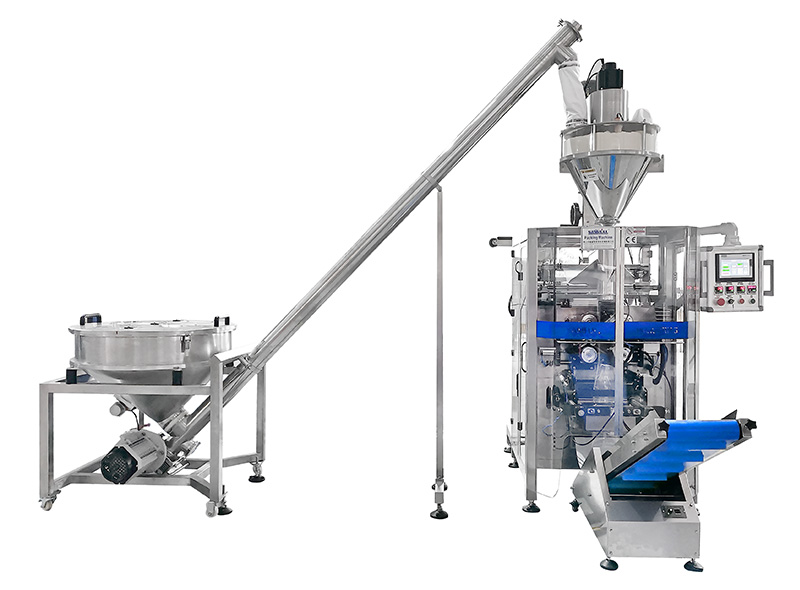

Powder Small Bag in Box Packaging Machine

Application:

Powder Small Bag in Box Packaging Machine is designed to handle packaging of powder products into small bags, and then placing those bags into boxes. This type of machine is suitable for a range of industries where precise dosing and efficient packaging are crucial.

Kindly reminder

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Bag dimension

2. Bag weight

3. Your product

4. Bag shape

5. Bag material

Videos of VFFS powder bag making connect with box packing:

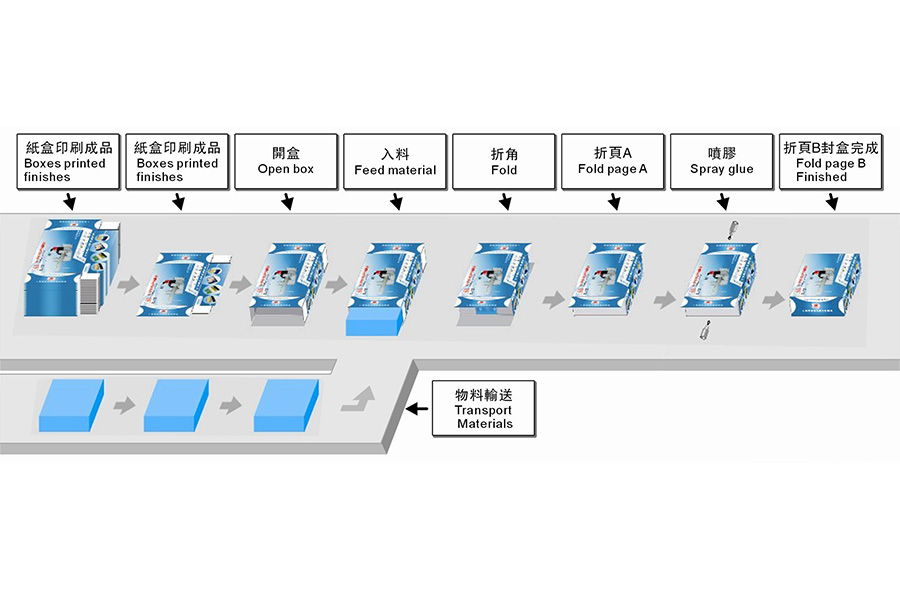

Machine Working Process:

Features:

International famous brand of electrical components such as PLC, touch screen, inverter, etc.

2. Adopt human-machine operation system.

3. Automatic stop when machine is overload.

4. Automatic reject lacking of package product and leaflet.

5. Automatic error displaying, alarming and finished products counting.

6. Stable performance, easy operation.

Functional Options

1. Inspection & Quality Control

Checkweigher

Metal Detector

X-ray Inspection System

Automatic Reject Device

2. Bag Handling & Conveying

Discharge Conveyor

Cooling / Air Conveyor for hot-sealed bags

Automatic Bag Flattening System

Bag Shaping / Forming Unit

3. Vacuum Packaging Options

In-line Vacuum Chamber System

For vacuuming finished bags before final sealing.

Nitrogen Flushing System (MAP)

Modified Atmosphere Packaging for maintaining freshness.

Vacuum + Nitrogen Combination

Used for coffee, nuts, and high-value food products.

4. Coffee Degassing Valve Solutions

Automatic Degassing Valve Applicator

Automatically applies one-way valves on bags (for roasted coffee beans).

Integrated Degassing Valve Feeding System

Ensures stable valve supply at high speeds.

Coffee-Specific Gas Flushing Calibration

Designed for coffee aroma retention and extended shelf-life.

5. Robotic Arm Applications

Robotic Bag Sorting

Robotic Pick-and-Place to Cartoner / Case Packer

Robotic Grouping / Stacking

Robotic Loading into Boxes, Trays, Buckets

Robotic Transfer to End-of-Line Equipment

6. Secondary Packaging

A. Bag-in-Bag Packaging

Automatic Bag-in-Bag Machine

Secondary VFFS or HFFS Machine

B. Cartoning Line

Carton Erector

Vertical/Horizontal Cartoner

Robotic Carton Loading

C. Bottle / Can / Jar Filling

Automatic Filling System

Capping, Sealing, Labeling

7. End-of-Line Automation

Case Erector

Case Packer (robotic/top-load/side-load)

Case Sealer

Robotic Palletizer (4/6-axis)

8. Coding & Labeling

Coding/printing system (inkjet printer, thermal printer, laser coder)

Automatic Labeler

9. Front-end Feeding & Preparation System

Powder Mixing Machine

Screw Conveyor / Auger Feeder

Bucket Elevator / Z-type Conveyor

Vibratory Feeder

Vacuum feeder