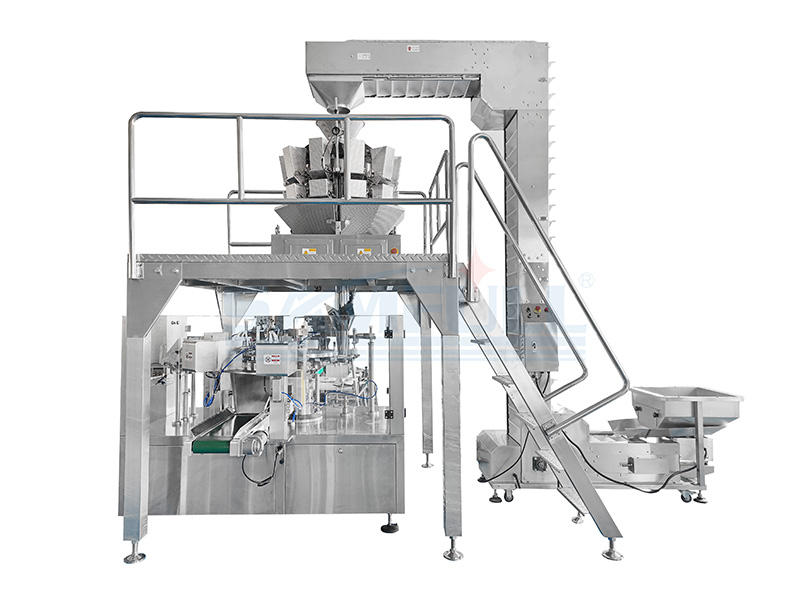

Rice Doypack Machine

Application

Rotary premade pouch doypack machine is suitable for powder, granule and liquid products by integrating with different measuring and weighing system.

Plus: We also offer different kinds of weighing system, like combination weigher for particle and granule, auger filler for powder, piston filler for liquid, etc.

Kindly reminder

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Bag dimension

2. Bag weight

3. Your product

4. Bag shape

5. Bag material

Video

Features:

1. Stainless steel appearance, beautiful and high-grade, stable operation;

2. Replace manual packaging, the production efficiency is increased, and the production cost is greatly reduced;

3. Adopt PLC control, touch screen operation, a wide range of use, set the speed of operation according to production capacity requirements;

4. Changing the size of the bags quickly and easily which can be adjusted by handle;

5. Automatic detection function, the pouch can be recycle used if these situation happens: bags can not open or open the bag incomplete, no feeding, no heat sealing;

6. It can be used in doypack bags, handbags, zipper bags, four-sided bags, three-sided bags, paper bags, M-shaped bags and other composite bags;

7. It can automatically perform the functions of suction bag, date printing, bag opening, materials filling, bag sealing, finished product output.

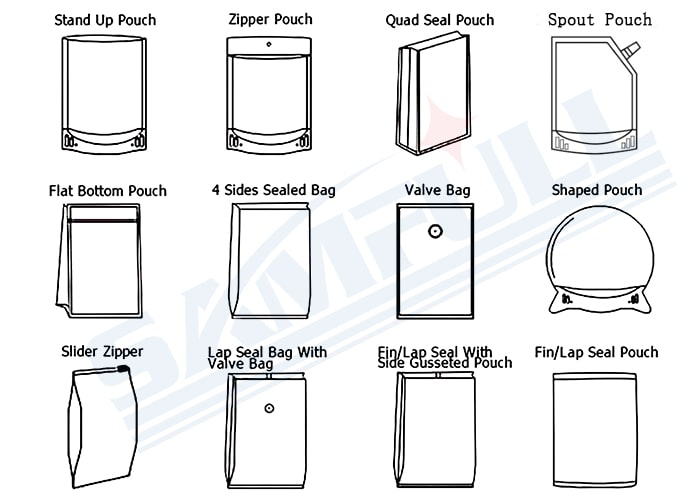

Bag Types:

Functional Options

1. Inspection & Quality Control

Checkweigher

Metal Detector

X-ray Inspection System

Automatic Reject Device

2. Bag Handling & Conveying

Discharge Conveyor

Cooling / Air Conveyor for hot-sealed bags

Automatic Bag Flattening System

Bag Shaping / Forming Unit

3. Robotic Arm Applications

Robotic Bag Sorting

Robotic Pick-and-Place to Cartoner / Case Packer

Robotic Grouping / Stacking

Robotic Loading into Boxes, Trays, Buckets

Robotic Transfer to End-of-Line Equipment

4. Secondary Packaging

A. Bag-in-Bag Packaging

Automatic Bag-in-Bag Machine

Secondary VFFS or HFFS Machine

B. Cartoning Line

Carton Erector

Vertical/Horizontal Cartoner

Robotic Carton Loading

C. Bottle / Can / Jar Filling

Automatic Filling System

Capping, Sealing, Labeling

5. End-of-Line Automation

Case Erector

Case Packer (robotic/top-load/side-load)

Case Sealer

Robotic Palletizer (4/6-axis)

6. Coding & Labeling

Coding/printing system (inkjet printer, thermal printer, laser coder)

Automatic Labeler

7. Front-end Feeding & Preparation System

Powder Mixing Machine

Screw Conveyor / Auger Feeder

Bucket Elevator / Z-type Conveyor

Vibratory Feeder

Vacuum feeder