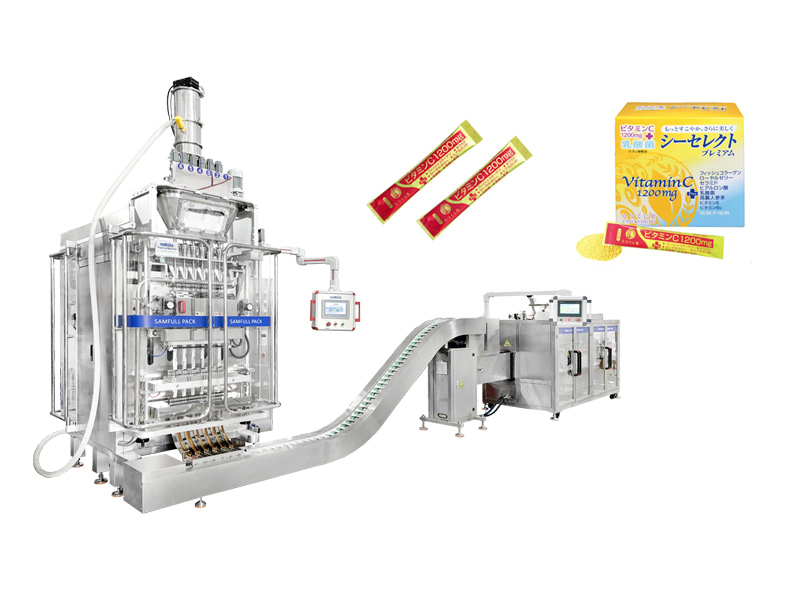

High Output Multilane Stickpack & Sachet Packaging Machine

Application

Samfull Multilane Stickpack & Sachet Packaging Machine is designed for high-output stick pack and sachet packaging applications. With 2–12 lanes available, they are suitable for powder, granule, liquid, and paste products, widely used in food, nutraceutical, pharmaceutical, and cosmetic industries. If your required speed is below 40 bags/min, a single-lane solution may be more suitable.

Kindly reminder

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Your product

2. Bag dimension

3. Bag weight

4. Bag shape

5. Output capacity

Videos

1. When Do You Need a Multilane Packing Machine?

A multilane solution is recommended in the following situations:

1.High production demand

When required output exceeds the capacity of a single-lane machine, multilane design significantly increases bags per minute without adding multiple standalone units.

2. Single-lane machines reach capacity limits

If your current stick or sachet machine cannot keep up with growing orders, upgrading to a multilane system is the most efficient solution.

3. Automation and labor cost reduction

Multilane machines operate with PLC control and centralized operation, reducing labor dependency and improving consistency.

4. OEM / contract packaging or regulated industries

Ideal for nutraceutical and pharmaceutical manufacturers that require stable, continuous, and hygienic high-speed production.

If your priority is productivity, automation, and long-term cost efficiency, a multilane machine is the better choice than operating multiple single-lane units.

2. Typical Industries and Applications

Samfull multilane packing machines are widely used in:

Food Industry

Instant drink powders, coffee, sugar, seasoning, nutritional powders

Stick pack and sachet formats

Nutraceutical & Health Products

Vitamin powders, collagen, protein powder, probiotics

Especially suitable for OEM and contract manufacturers

Pharmaceutical Industry

Single-dose powders and liquids

Designed for accuracy, hygiene, and stable continuous operation

Cosmetics & Personal Care

Sample sachets for creams, gels, shampoos, and liquids

Pet Food & Agricultural Products

Single-dose pet supplements, seeds, fertilizer sachets

3. Inquiry Information (For Accurate Machine Selection)

To recommend the most suitable multilane solution, please provide the following information:

Product type: powder / granule / liquid / paste

Packaging format: stick pack or sachet

Target capacity: bags per minute or units per hour

Bag size range: length × width

Filling weight range: g or ml

Packaging material: laminated film / aluminum foil / others

Line integration required: yes / no

Optional Configuration

1. Inspection & Quality Control Modules

1. Checkweigher (Weight Checking System)

2. Metal Detector

3. X-ray Inspection System (for high-end factories)

4. Automatic Reject System

2. Sorting & Conveying

1. Discharge Conveyor

2. Stick Pack / Sachet Collating System

3. High-speed Lane Diverter Conveyor

3. Counting & Grouping Systems

1. Automatic Counting Machine

2. Multilane Automatic Counting & Grouping Unit

3. Stacking System (for bundle packs)

4. Secondary Packaging Options

A. Cartoning

1. Automatic Carton Erector

2. Vertical / Horizontal Cartoning Machine

3. Multi-pack counting + automatic cartoning line

B. Bag-in-Bag Packaging

1. Automatic Bag-in-Bag Packaging System

2. Secondary VFFS / HFFS Machine

C. Jar / Can Filling

1. Stick Pack to Can/Bottle Filling Line

2. Automatic Capping and Labeling Systems

5. End-of-Line Packaging

1. Case Erector

2. Case Packer (Drop-type / Side-load)

3. Case Sealer

4. Robotic Palletizer

6. Labeling & Traceability Systems

1. Inkjet or Laser Coding System

2. Automatic Labeling Machine

7. Robotic Arm Applications (Pick-and-Place Robots)

1. Robotic Bag Sorting

2. Automatically picks and orients bags for downstream equipment.

3. Robotic Bag Loading

4. Loads single bags or grouped bags into:

Cartons

Trays

Display boxes

Buckets/cans

5. Robotic Grouping System

High-speed grouping of pouches/bags based on preset patterns.

6. Robotic Feeding to Case Packer

Ensures continuous feeding without manual intervention.

8. Front-end Feeding & Preparation System

Powder Mixing Machine

Screw Conveyor / Auger Feeder

Bucket Elevator / Z-type Conveyor

Vibratory Feeder

Vacuum feeder

Features:

1. The whole machine is controlled by PLC program. The function parameters are set by man-machine interface touch screen. The main electrical components are famous brands at home and abroad. The control is stable and the operation is simple;

2. It has functions of automatic filling, measuring, bag making, sealing, printing batch, counting, and finished product output;

3. The horizontal seal adopts independent servo control, the structure is simple and reliable;

4. The film running stable and has the function of cursor correction and compensation;

5. The storage bin adopts continuous automatic vacuum feeding;

6. The filling machine is detachable, easy to install, easy to clean and disinfect;

7. 4 to 12 lanes can be packed according to the width of the bag;

8. The machine can be connected with the mending line and automatic cartonning equipment to be a complete line.