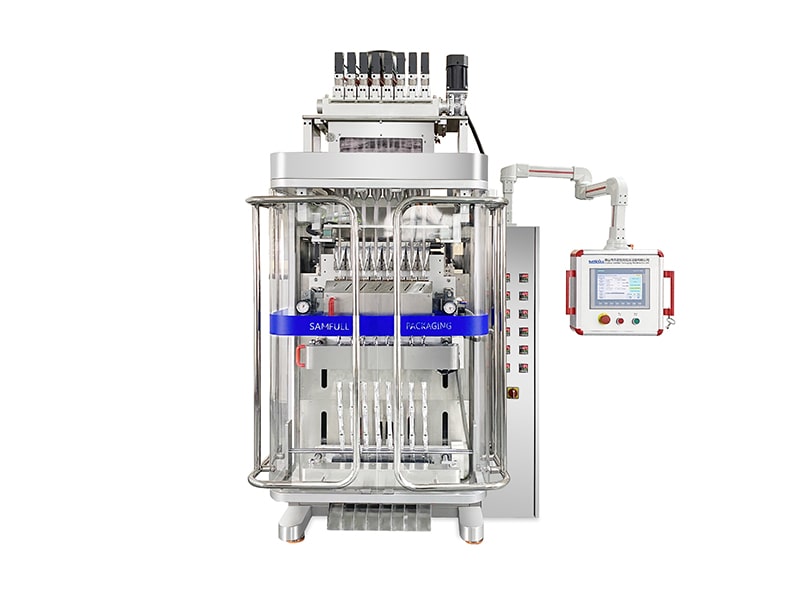

Irregular Shape Liquid Stick Pack Packaging Machine

Application

We offer 4 to 12 lanes multi-lane sachet and stick pack packaging machine for pharmacy energy gel jelly, fruit pulp juice, with high production capacity of 100-540 sachets in per minute.

At the same time, we also provide secondary packaging equipment, such as counting device, cartoning machine and bag-in-bag vertical packaging machine.

Kindly reminder

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Your product

2. Bag dimension

3. Bag weight

4. Bag shape

5. Output capacity

Videos

Features:

1. The whole machine is controlled by PLC program. The function parameters are set by man-machine interface touch screen. The main electrical components are famous brands at home and abroad. The control is stable and the operation is simple;

2. It has functions of automatic filling, measuring, bag making, sealing, printing batch, counting, and finished product output;

3. The horizontal seal adopts independent servo control, the structure is simple and reliable;

4. The film running stable and has the function of cursor correction and compensation;

5. The storage bin adopts continuous automatic vacuum feeding;

6. The filling machine is detachable, easy to install, easy to clean and disinfect;

7. 4 to 12 lanes can be packed according to the width of the bag;

8. The machine can be connected with the mending line and automatic cartonning equipment to be a complete line.

Optional Configuration

1. Inspection & Quality Control Modules

1. Checkweigher (Weight Checking System)

2. Metal Detector

3. X-ray Inspection System (for high-end factories)

4. Automatic Reject System

2. Sorting & Conveying

1. Discharge Conveyor

2. Stick Pack / Sachet Collating System

3. High-speed Lane Diverter Conveyor

3. Counting & Grouping Systems

1. Automatic Counting Machine

2. Multilane Automatic Counting & Grouping Unit

3. Stacking System (for bundle packs)

4. Secondary Packaging Options

A. Cartoning

1. Automatic Carton Erector

2. Vertical / Horizontal Cartoning Machine

3. Multi-pack counting + automatic cartoning line

B. Bag-in-Bag Packaging

1. Automatic Bag-in-Bag Packaging System

2. Secondary VFFS / HFFS Machine

C. Jar / Can Filling

1. Stick Pack to Can/Bottle Filling Line

2. Automatic Capping and Labeling Systems

5. End-of-Line Packaging

1. Case Erector

2. Case Packer (Drop-type / Side-load)

3. Case Sealer

4. Robotic Palletizer

6. Labeling & Traceability Systems

1. Inkjet or Laser Coding System

2. Automatic Labeling Machine

7. Robotic Arm Applications (Pick-and-Place Robots)

1. Robotic Bag Sorting

2. Automatically picks and orients bags for downstream equipment.

3. Robotic Bag Loading

4. Loads single bags or grouped bags into:

Cartons

Trays

Display boxes

Buckets/cans

5. Robotic Grouping System

High-speed grouping of pouches/bags based on preset patterns.

6. Robotic Feeding to Case Packer

Ensures continuous feeding without manual intervention.