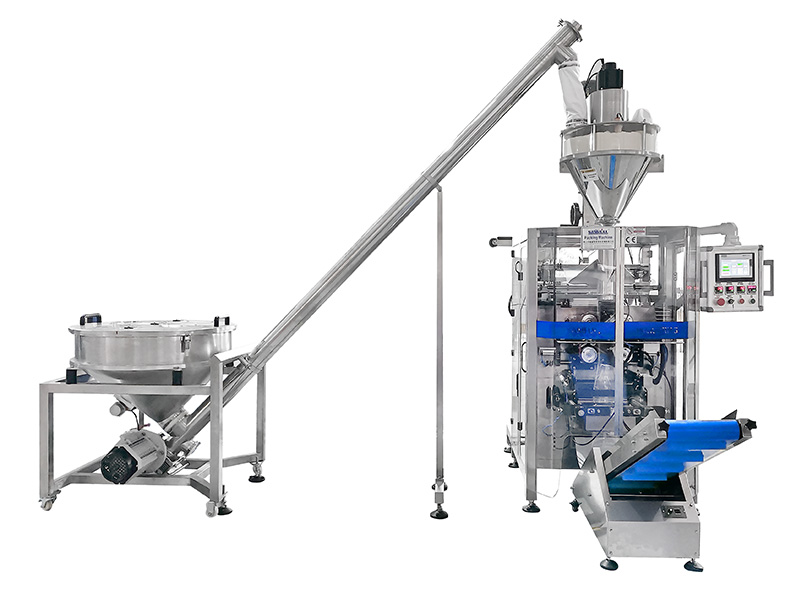

Milk Powder VFFS Form Fill & Seal Packing Machine

Application

This milk powder VFFS (Vertical Form Fill Seal) machine is a specialized packaging machine used to efficiently and automatically package milk powder into vertical pouches. The VFFS technology is a popular choice for packaging various powder products, including milk powder, flour powder, drink powder, seasong powder, etc.

Kindly reminder

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Your product

2. Bag dimension

3. Bag weight

4. Bag shape

5. Output capacity

Videos

VFFS powder bag making connect with box packing:

Bag Shape Options

1. Pillow bag

2. Gusset bag

3. Flat bottom stand up bag

4. Quad seal stand up bag

5. Brick shape bag

6. Bag with hanging hole

7. Bag with easy tear notch

Functional Options

1. Inspection & Quality Control

Checkweigher

Metal Detector

X-ray Inspection System

Automatic Reject Device

2. Bag Handling & Conveying

Discharge Conveyor

Cooling / Air Conveyor for hot-sealed bags

Automatic Bag Flattening System

Bag Shaping / Forming Unit

3. Vacuum Packaging Options

In-line Vacuum Chamber System

For vacuuming finished bags before final sealing.

Nitrogen Flushing System (MAP)

Modified Atmosphere Packaging for maintaining freshness.

Vacuum + Nitrogen Combination

Used for coffee, nuts, and high-value food products.

4. Coffee Degassing Valve Solutions

Automatic Degassing Valve Applicator

Automatically applies one-way valves on bags (for roasted coffee beans).

Integrated Degassing Valve Feeding System

Ensures stable valve supply at high speeds.

Coffee-Specific Gas Flushing Calibration

Designed for coffee aroma retention and extended shelf-life.

5. Robotic Arm Applications

Robotic Bag Sorting

Robotic Pick-and-Place to Cartoner / Case Packer

Robotic Grouping / Stacking

Robotic Loading into Boxes, Trays, Buckets

Robotic Transfer to End-of-Line Equipment

6. Secondary Packaging

A. Bag-in-Bag Packaging

Automatic Bag-in-Bag Machine

Secondary VFFS or HFFS Machine

B. Cartoning Line

Carton Erector

Vertical/Horizontal Cartoner

Robotic Carton Loading

C. Bottle / Can / Jar Filling

Automatic Filling System

Capping, Sealing, Labeling

7. End-of-Line Automation

Case Erector

Case Packer (robotic/top-load/side-load)

Case Sealer

Robotic Palletizer (4/6-axis)

8. Coding & Labeling

Coding/printing system (inkjet printer, thermal printer, laser coder)

Automatic Labeler

9. Front-end Feeding & Preparation System

Powder Mixing Machine

Screw Conveyor / Auger Feeder

Bucket Elevator / Z-type Conveyor

Vibratory Feeder

Vacuum feeder

Functions & Features Of Milk Powder VFFS Machine

1. Vertical Forming: The machine forms a vertical tube from a flat roll of packaging material (usually a flexible film). The tube is created by sealing the edges of the film, forming a continuous cylinder.

Filler System: For milk powder, an auger filler or a volumetric cup filler is commonly used. The auger filler measures and dispenses a precise amount of milk powder into each pouch, while the volumetric cup filler uses pre-measured cups to fill the powder.

2. Film Roll Unwinding System: The machine is equipped with a film roll unwinding system that supplies the packaging material. The film is pulled down and shaped into the vertical tube, ready to be filled.

Sealing Mechanism: The top and bottom ends of the vertical tube are sealed to create individual pouches. The sealing mechanism may use heat sealing or impulse sealing, depending on the type of packaging material used.

3. PLC Control and HMI: The machine's operations are controlled by a Programmable Logic Controller (PLC), which provides precise control over the packaging process. The Human-Machine Interface (HMI) allows operators to set parameters, adjust settings, and monitor the machine's performance.

4. Adjustable Bag Length and Width: The machine can be easily adjusted to produce pouches with different lengths and widths to suit specific packaging requirements.

5. Date and Batch Coding: A coding system is often integrated into the machine to print essential information on each pouch, such as the date of manufacture, expiration date, batch numbers, and other product-related details.

6. Safety Features: Safety measures, such as emergency stop buttons, safety interlocks, and safety guards, are incorporated to ensure operator safety during machine operation.