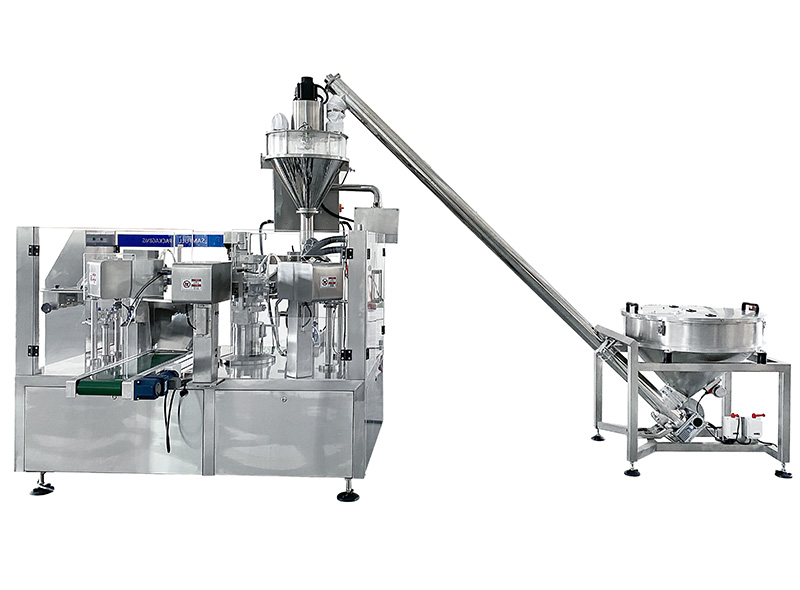

Coffee Premade Pouch (Doypack) Filling and Sealing Machine

Application

The coffee premade pouch filling and sealing machine is a piece of equipment used in the food packaging industry to automate the process of filling and sealing pre-made pouches with coffee beans, ground coffee and other similar products. These machines are designed to improve efficiency, reduce manual labor, and ensure consistent packaging quality.

Kindly reminder

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Your product

2. Bag dimension

3. Bag weight

4. Bag shape

5. Output capacity

Videos:

Whole bean and ground coffee premade pouch samples

Features:

1. The equipment frame is made of 304 stainless steel, which meets the food QS and pharmaceutical GMP hygiene standards;

2. The machine is controlled by PLC, and the touch screen man-machine interface is more convenient;

3. The working speed of this machine can be adjusted steplessly by the frequency conversion speed regulating device within the specified range;

4. Overload protection, safety device, automatic alarm prompt when the machine working pressure is abnormal or the heating pipe fails;

5. It can intelligently detect whether the bag is opened and whether the bag is intact. In the case of inappropriate feeding, no feeding or heat sealing, no waste of the bag, which can save considerable costs for users;

6. Imported tolerance plastic bearings are used in some components, no need to add oil, reducing food pollution;

7. Use prefabricated product packaging bags with perfect patterns, good sealing effect, and high-grade finished products;

8. It can pack prefabricated bags and paper bags made of multi-layer composite film, single-layer PE, PP and other materials, with a wide range of packaging;

9. Safety performance: The machine will stop automatically when the door is opened to prevent accidental injury by the machine;

Bag type:

doypack 2.zipper bag 3.flat bottom stand up pouch 4.spouted pouch 5.handbags 6.three side sealing bag 7.four side sealing bags 8.paper bags 9.other composite prefabricated bags

Functional Options

1. Inspection & Quality Control

Checkweigher

Metal Detector

X-ray Inspection System

Automatic Reject Device

2. Bag Handling & Conveying

Discharge Conveyor

Cooling / Air Conveyor for hot-sealed bags

Automatic Bag Flattening System

Bag Shaping / Forming Unit

3. Robotic Arm Applications

Robotic Bag Sorting

Robotic Pick-and-Place to Cartoner / Case Packer

Robotic Grouping / Stacking

Robotic Loading into Boxes, Trays, Buckets

Robotic Transfer to End-of-Line Equipment

4. Secondary Packaging

A. Bag-in-Bag Packaging

Automatic Bag-in-Bag Machine

Secondary VFFS or HFFS Machine

B. Cartoning Line

Carton Erector

Vertical/Horizontal Cartoner

Robotic Carton Loading

C. Bottle / Can / Jar Filling

Automatic Filling System

Capping, Sealing, Labeling

5. End-of-Line Automation

Case Erector

Case Packer (robotic/top-load/side-load)

Case Sealer

Robotic Palletizer (4/6-axis)

6. Coding & Labeling

Coding/printing system (inkjet printer, thermal printer, laser coder)

Automatic Labeler

7. Front-end Feeding & Preparation System

Powder Mixing Machine

Screw Conveyor / Auger Feeder

Bucket Elevator / Z-type Conveyor

Vibratory Feeder

Vacuum feeder