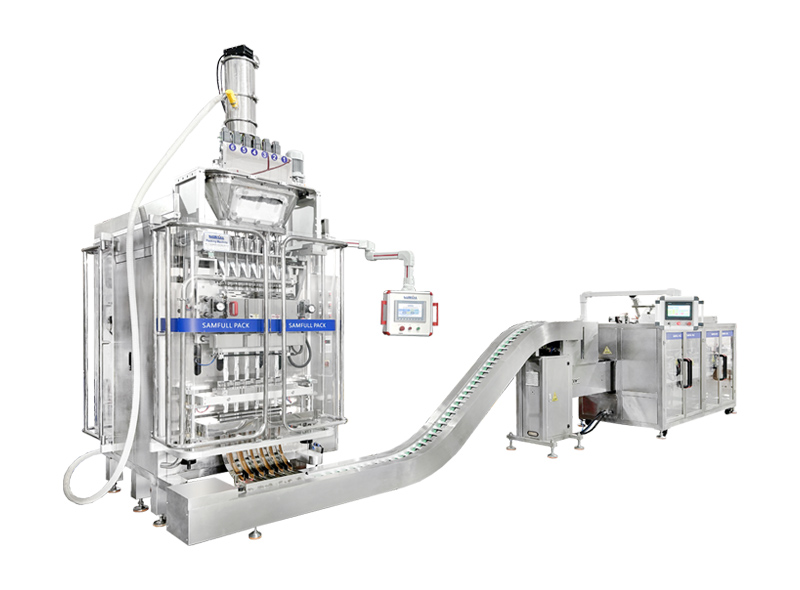

Powder Sachet & Stick Counting and Paper Box Repacking Line

Application:

Powder Stick Counting and Carton Packing Line is a comprehensive packaging system designed to automate the process of counting individual powdered product stick packs and then packaging them into cartons for distribution. This type of production line is commonly used in industries such as food, pharmaceuticals, and supplements, where single-serving stick packs need to be efficiently counted and grouped for bulk distribution.

Kindly reminder

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Bag dimension

2. Bag weight

3. Your product

4. Bag shape

5. Bag material

Videos:

Machine Working Process

1. Stick Pack Counting and Collating:

Stick packs are fed into the counting and collating system, which arranges a specific number of stick packs into a single batch or set. The number of stick packs in each batch can be adjusted based on packaging requirements.

2. Counting Mechanism:

The counting mechanism accurately counts the stick packs as they move along the conveyor.

3. Batch Formation:

Once the desired number of stick packs is counted, the batches are formed and collected in a staging area.

4. Carton Loading:

Empty cartons are loaded onto the carton packing machine's conveyor system.

5. Batch Insertion:

The formed batches of stick packs are inserted into the cartons. This can be done manually or through an automated system that places the batches in a specific arrangement inside the carton.

6. Carton Sealing:

Once the cartons are filled with the required number of stick pack batches, the carton sealing mechanism engages to close and seal the cartons. This might involve adhesive tape, glue, or other sealing methods.

7. Optional Steps:

Depending on the product and packaging requirements, additional steps might be included in the process:

Printing date codes, batch numbers, and product information on each carton for traceability.

Applying labels or stickers to the cartons for branding and identification.

Optional Configuration

1. Inspection & Quality Control Modules

1. Checkweigher (Weight Checking System)

2. Metal Detector

3. X-ray Inspection System (for high-end factories)

4. Automatic Reject System

2. Sorting & Conveying

1. Discharge Conveyor

2. Stick Pack / Sachet Collating System

3. High-speed Lane Diverter Conveyor

3. Counting & Grouping Systems

1. Automatic Counting Machine

2. Multilane Automatic Counting & Grouping Unit

3. Stacking System (for bundle packs)

4. Secondary Packaging Options

A. Cartoning

1. Automatic Carton Erector

2. Vertical / Horizontal Cartoning Machine

3. Multi-pack counting + automatic cartoning line

B. Bag-in-Bag Packaging

1. Automatic Bag-in-Bag Packaging System

2. Secondary VFFS / HFFS Machine

C. Jar / Can Filling

1. Stick Pack to Can/Bottle Filling Line

2. Automatic Capping and Labeling Systems

5. End-of-Line Packaging

1. Case Erector

2. Case Packer (Drop-type / Side-load)

3. Case Sealer

4. Robotic Palletizer

6. Labeling & Traceability Systems

1. Inkjet or Laser Coding System

2. Automatic Labeling Machine

7. Robotic Arm Applications (Pick-and-Place Robots)

1. Robotic Bag Sorting

2. Automatically picks and orients bags for downstream equipment.

3. Robotic Bag Loading

4. Loads single bags or grouped bags into:

Cartons

Trays

Display boxes

Buckets/cans

5. Robotic Grouping System

High-speed grouping of pouches/bags based on preset patterns.

6. Robotic Feeding to Case Packer

Ensures continuous feeding without manual intervention.

8. Front-end Feeding & Preparation System

Powder Mixing Machine

Screw Conveyor / Auger Feeder

Bucket Elevator / Z-type Conveyor

Vibratory Feeder

Vacuum feeder